Shielding Innovation, Ensuring Compliance

Our EMC Chambers are engineered to provide optimal environments for electromagnetic compatibility (EMC) testing, ensuring your devices meet international standards for electromagnetic interference (EMI) and electromagnetic susceptibility (EMS). Whether for R&D, compliance testing, or pre-certification, our chambers offer unparalleled precision and reliability.

Establishing Your Own Chamber Demands Collaboration The EMC chamber process offers a comprehensive solution that includes consulting, validation, and verification. It involves various stages, beginning from the consulting. Our expert team will manage each phase, keeping you informed every step of the way. Lets See the Each Step.

Design the perfect EMC chamber tailored to your specific testing needs. Provide your details, such as name, email, phone number, industry type, compliance standards, DUT size, and testing requirements. Specify the application, including automotive, military & aerospace, telecom, or multimedia. Choose chamber types like radiated emissions or immunity testing, and select standards for full compliance, pre-compliance, or a combination chamber.

Design the perfect EMC chamber tailored to your specific testing needs. Provide your details, such as name, email, phone number, industry type, compliance standards, DUT size, and testing requirements. Specify the application, including automotive, military & aerospace, telecom, or multimedia. Choose chamber types like radiated emissions or immunity testing, and select standards for full compliance, pre-compliance, or a combination chamber.

Design the perfect EMC chamber tailored to your specific testing needs. Provide your details, such as name, email, phone number, industry type, compliance standards, DUT size, and testing requirements. Specify the application, including automotive, military & aerospace, telecom, or multimedia. Choose chamber types like radiated emissions or immunity testing, and select standards for full compliance, pre-compliance, or a combination chamber.

Your Journey to a Customized Chamber Begins Here.

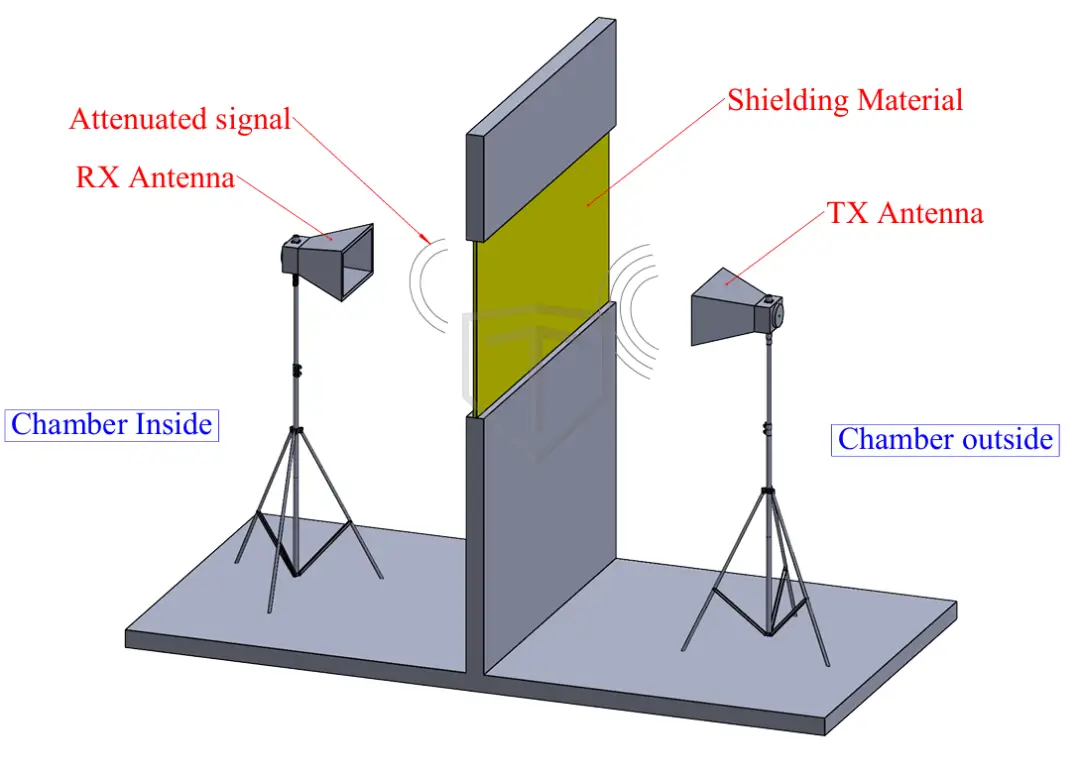

Shielding Effectiveness is the cornerstone of reliable EMC testing. It ensures that electromagnetic chambers provide a controlled, interference-free environment necessary for accurate and repeatable measurements.

By isolating test setups from external noise and preventing internal signal leakage, SE upholds the integrity of test results, supports compliance with industry standards, and enables the development of robust, interference-resilient technologies.

Tekiknow Chamber provides a Shield effectiveness of 100dB, with an extended performance reaching 120dB. This extended performance is typically utilized in high-performance applications and specific high-frequency requirements.

Copyright © 2024 – Tekiknow – All Rights Reserved Designed By Clemence Web Solutions.,